Exploring the Physics Behind High-Precision Measurements

Exploring the Physics Behind High-Precision Measurements

Blog Article

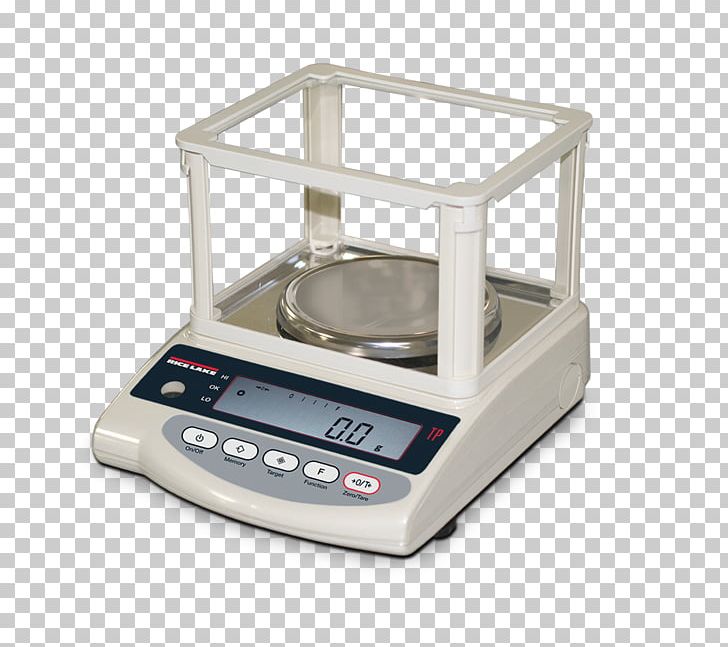

In the world of scientific research and industrial applications, the need for accuracy in measurements cannot be overstated. High-precision laboratory analytical balances play a critical role in ensuring that data collected is reliable and reproducible. These instruments are vital in fields such as pharmaceuticals, food production, and materials science, where even the slightest variation in weight can lead to significant differences in outcomes.

W&J Instrument stands out as a leading manufacturer and supplier of an extensive range of electronic balances, moisture analyzers, viscometers, and other essential laboratory instruments. With a commitment to precision and quality, their products are engineered to meet the demanding standards of professionals who require meticulous measurements. Understanding the physics behind these high-precision instruments not only elucidates their functionality but also highlights the importance of technology in enhancing measurement accuracy within diverse laboratory settings.

Understanding High-Precision Instruments

High-precision laboratory analytical balances are essential tools in many scientific and industrial applications. These instruments allow researchers to measure small quantities of materials with incredible accuracy, making them indispensable in fields such as pharmaceuticals, chemistry, and environmental science. The design and technology behind these balances are specifically tailored to minimize errors caused by external factors, ensuring the reliability of results.

The core functionality of high-precision balances relies on advanced sensing technology and meticulous engineering. Instruments like those produced by W&J Instrument utilize electromagnetic force restoration or load cell technology to provide precise readings. This ensures that even the slightest changes in weight can be detected, enabling scientists to perform experiments where accuracy is crucial. Additionally, these balances often feature built-in temperature and humidity compensation to mitigate environmental influences that may affect measurements.

Calibration is another critical aspect of maintaining high-precision instruments. Over time, even the most sophisticated balances can drift from their calibrated state due to factors such as wear and tear or changes in environmental conditions. Regular calibration against certified weights allows users to maintain confidence in their measurements. By ensuring that instruments are consistently accurate, laboratories can produce reliable data that reinforces scientific findings and contributes to advancements in various fields.

Key Technologies in Measurement

High-precision laboratory analytical balances rely on advanced technologies to achieve accurate measurements. One such technology is electromagnetic force restoration, which utilizes electromagnetic forces to balance the weight of the sample placed on the scale. This method allows for exceptional sensitivity and responsiveness, enabling the balance to measure small variations in weight with remarkable precision. The integration of this technology helps laboratory professionals obtain reliable results, crucial for research and quality control applications.

Another important technology is the use of digital signal processing. Modern analytical balances are equipped with high-resolution load cells that convert mechanical force into an electrical signal. This signal is then processed digitally, reducing noise and improving measurement accuracy. Digital signal processing enhances the stability of the reading and minimizes drift, which is particularly beneficial when working with lightweight samples that require high sensitivity for accurate measurement.

Additionally, the implementation of environmental controls within analytical balances contributes significantly to measurement precision. Factors such as air currents, temperature fluctuations, and vibrations can affect the accuracy of readings. High-precision balances often come with built-in draft shields and temperature compensation features, which help mitigate these external influences. By ensuring a controlled measurement environment, laboratories can achieve consistent and dependable results, reinforcing the importance of technology in high-precision measurements.

Applications of Electronic Balances

Electronic balances play a crucial role in various fields, from scientific research to industrial applications. In laboratories, they are indispensable for precise mass measurements, which are essential for experiments in chemistry, biology, and physics. Researchers rely on high-precision balances to ensure accuracy in their quantitative analyses, enabling them to detect minute changes in sample weights that can influence experimental outcomes. These balances are designed to minimize environmental factors, allowing for consistent and reliable measurements even in sensitive laboratory settings.

In the pharmaceutical industry, electronic balances are vital for formulation and quality control processes. Accurate weight measurements are necessary to ensure the correct dosage of active ingredients in medications, which directly impacts efficacy and safety. High-precision balances assist pharmacists and scientists in preparing formulations by providing real-time weight feedback, ensuring compliance with stringent regulatory standards. This reliability also extends to research and development, where precise measurements can lead to innovative formulations and improved drug delivery systems.

Additionally, electronic balances find extensive use in manufacturing and quality assurance across various industries. They facilitate operations such as ingredient batching and product inspections, contributing to consistent product quality. In food production, for instance, accurate weight measurements can affect consistency and safety, ensuring that products meet industry regulations. Electronic balances enable operators to monitor and control weight throughout the production process, ultimately leading to higher quality and efficiency in manufacturing operations.

Innovations in Laboratory Instrumentation

Recent advancements in high-precision laboratory analytical balances have revolutionized the way researchers and scientists conduct measurements. Modern balances are now equipped with sophisticated technology that allows for improved accuracy and reliability. These innovations include enhanced load cell designs and advanced algorithms that compensate for environmental factors such as temperature fluctuations and vibrations, ensuring that measurements remain stable and credible.

In addition to hardware upgrades, software developments play a crucial role in elevating the functionalities of analytical balances. User-friendly interfaces and connectivity options have transformed how data is recorded and analyzed. Many contemporary balances now offer integration with laboratory management systems, enabling seamless data transfer and real-time monitoring, which significantly enhances workflow efficiency and data integrity.

Find Out More

Furthermore, companies like W&J Instrument are at the forefront of these innovations, continuously developing new features such as touchless controls and customizable settings tailored to specific laboratory needs. Such advancements not only facilitate precision but also improve user experience, making high-precision measurements more accessible and efficient for various applications in laboratories across different fields.

Report this page